-

Jamuna Engineering Company

Jamuna Engineering Companyis the one of the leading company of Jamuna Group of Industries. -

Jamuna Engineering Company

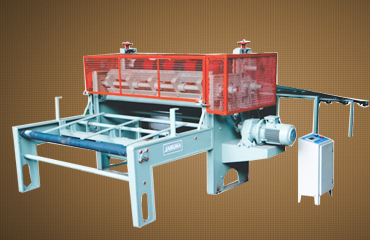

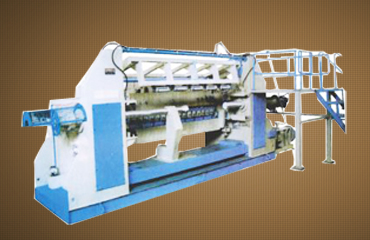

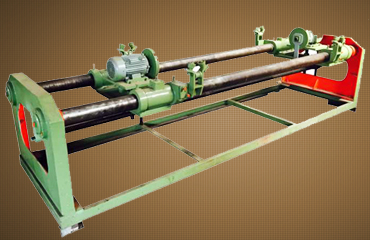

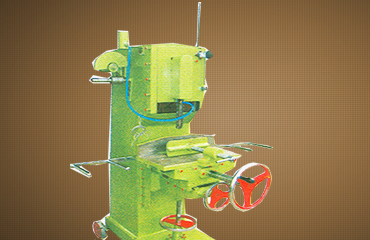

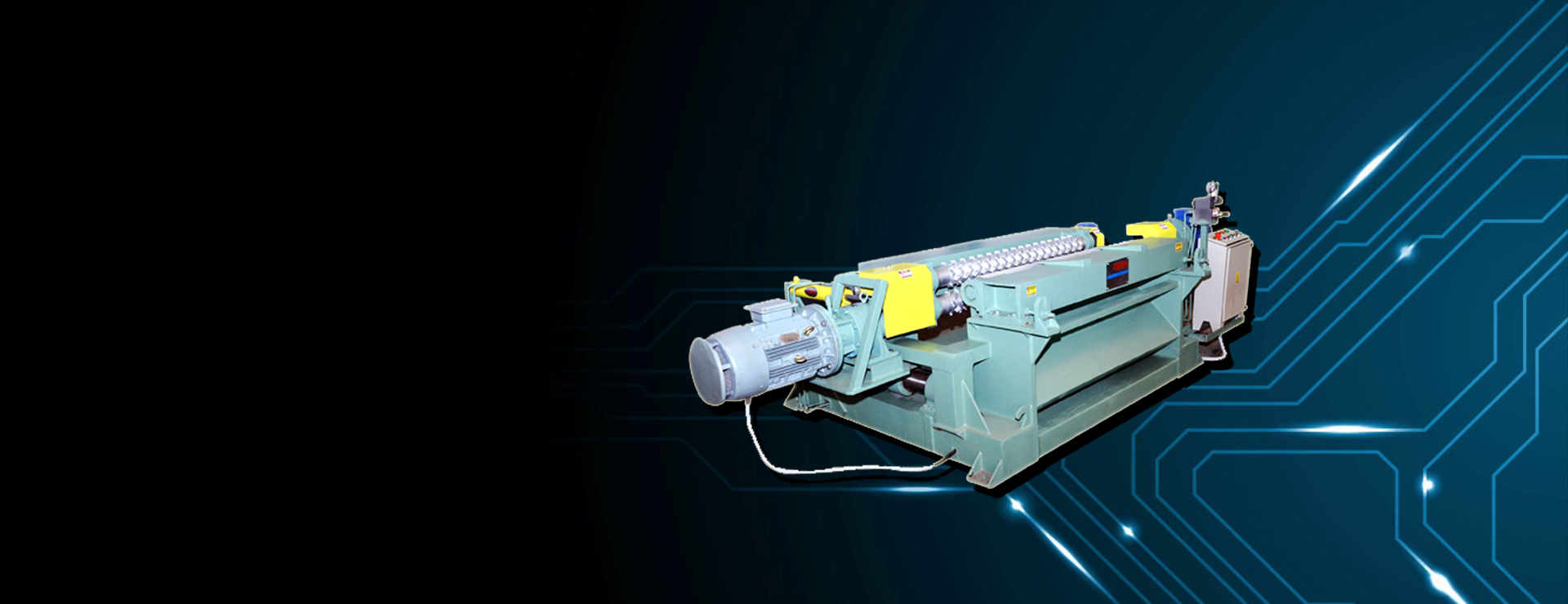

Jamuna Engineering Company is manufacturing Plywood machinery, Peeling machine and Wood working machinery's since 1984.

Our Products

We are well reckoned as one of the Veneer Cutting Chopping Machine , rotary veneer lathe machine, rotary veneer lathe machine 108" manufacturers, based in India.

Jamuna Engineering Company, Yamuna Nagar India, established in the year 1986, started its industrial career, by building small scale machines.

Jamuna Engineering Company

Jamuna Engineering Company is the one of the leading company of Jamuna Group of Industries. Jamuna Engineering Company is manufacturing Plywood machinery, Peeling machine and Wood working machinery's since 1984. Our machinery's are working all around Asian countries such as- Bangladesh, Bhutan, Afghanistan, Indonesia, Nepal, Pakistan, Malaysia, Brunei, Sri Lanka, Singapore, Africa, Vietnam, Philippines, Uzbekistan, UAE, US, Korea, Iran, Lebanon, Saudi Arabia etc. and all over India.

At Jamuna Engineering Company, quality is given the top most priority.

- Company Profile

- Certified Company

- Delivery Ontime

- Best Quality

OUR TEAM

Being client focused organization, we work for cent percent client satisfaction by catering their bulk requirements of Melting Furnace, Industrial Melting Furnace, Particle Board Machinery, Plywood Machinery, Prelam Machinery, Belt Sanding machine, Gullotine Jointers, Rotary Dryer, Side Sanding Machine, etc.

Mr. Sandeep Singh Sehmi

Chief Executive Officer

Mr. Gurdeep Singh Sehmi

Director of the board